Precision Machining Services

Start A New CNC Quote

STEP | STP | SLDPRT | IPT | PRT | SAT files

- All uploads are secure and confidential.

What is Precision CNC Machining

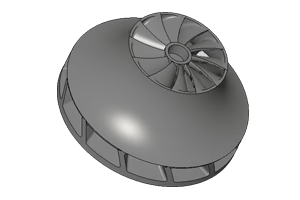

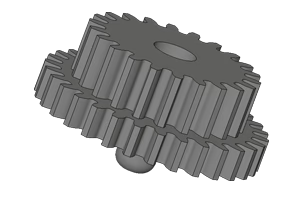

Precision machining utilizes advanced CNC technology to produce highly accurate parts for industries like aerospace, medical devices, and electronics. This process ensures that each component meets exact specifications for size, shape, and function, making it ideal for detailed and complex designs. CNC precision machining is crucial for creating high-quality parts such as gears, brackets, and enclosures, offering consistent production and tight tolerances.

With Arapidtools’s precision CNC services, industries can achieve exceptional accuracy and reliability, ensuring that each part functions perfectly within its application. Whether for small-scale prototypes or large-volume production, we deliver durable and dependable components that meet the highest standards.

Our Precision Machining Services

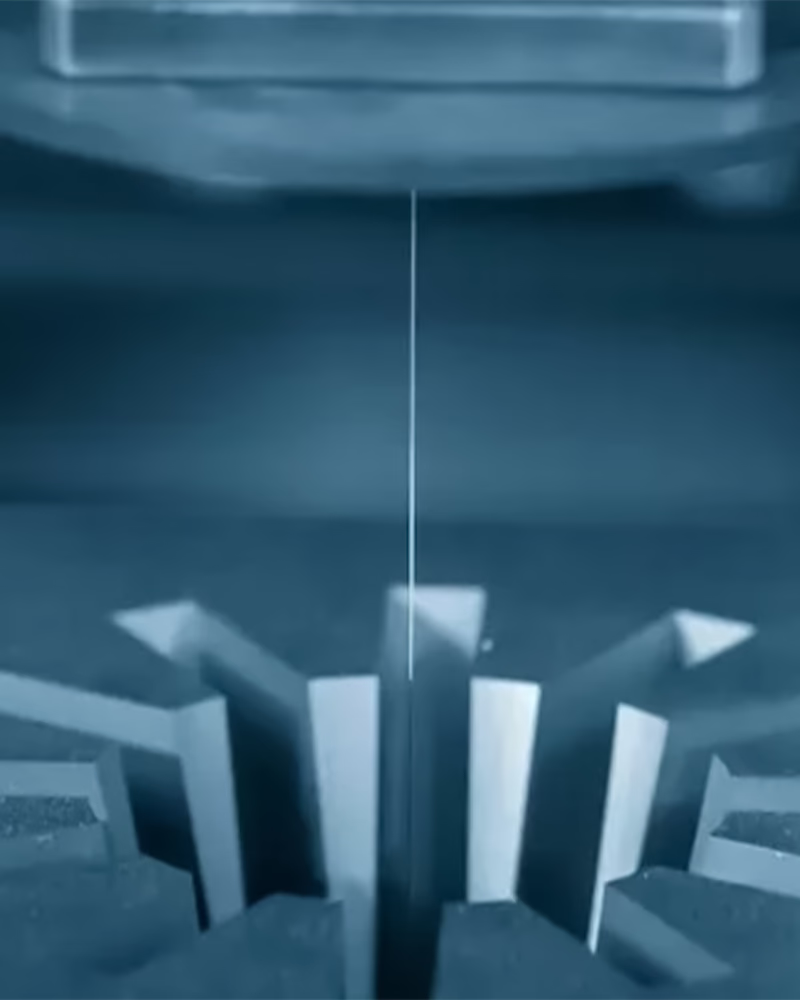

Wire EDM Service

| Capability | Details/Specifications |

|---|---|

| Material Compatibility | Stainless Steel, Titanium, Aluminum, Tool Steel, Copper |

| Tolerance | ± 0.0001 inches (0.0025 mm) or better (based on material and thickness) |

| Maximum Workpiece Size |

Length: 16 inches (400 mm) Width: 12 inches (300 mm) Height: 8 inches (200 mm) |

| Cutting Speed | Up to 300 mm²/min (specific to material and thickness) |

| Surface Finish | As fine as Ra 0.2 µm |

| Maximum Cutting Thickness | Up to 12 inches (300 mm) – varies based on material |

| Wire Diameter Range | 0.004 inches (0.1 mm) to 0.012 inches (0.3 mm) |

Mirror EDM Service

Mirror EDM delivers high-precision, mirror-reflective parts, expertly handling intricate shapes with tight tolerances on hard materials where conventional tools fail. Serving industries from aerospace to electronics, our Mirror EDM ensures unparalleled precision, consistently capturing complex geometries and intricate contours.

| Capability | Details/Specifications |

|---|---|

| Material Compatibility | Stainless Steel, Titanium, Aluminum, Tool Steel, Copper |

| Surface Finish | Achievable down to Ra 0.05 µm or better (based on material and process parameters) |

| Tolerance | ± 0.00005 inches (0.0013 mm) or better (depending on material and thickness) |

| Maximum Workpiece Size | Length: 16 inches (400 mm) Width: 12 inches (300 mm) Height: 8 inches (200 mm) |

| Maximum Cutting Thickness | Up to 10 inches (250 mm) – |

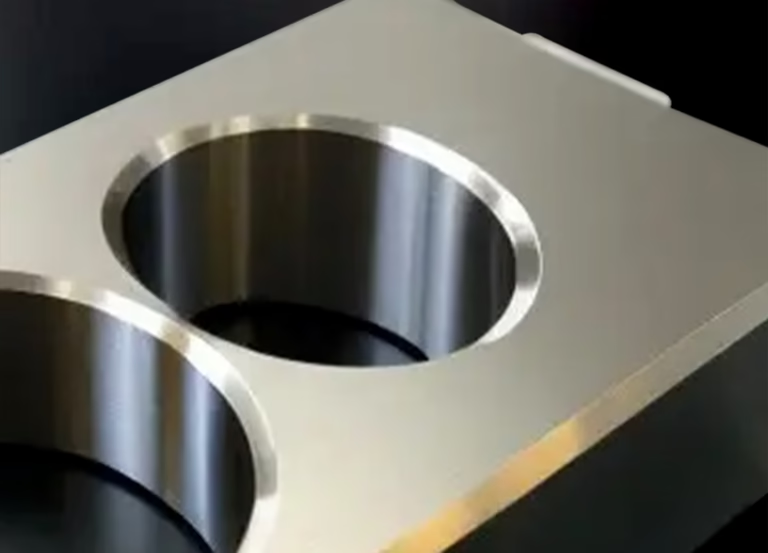

Grinding Service

Arapidtools’s advanced manufacturing facility features high-precision grinding machines ideal for producing metal parts with tight tolerances. Our versatile grinding services accommodate both small and complex geometries, utilizing precision wheels for controlled material removal and polished finishes. This efficient process reduces costs, wear, and errors. Trust our expert team to deliver the perfect grinding solution for your project.

| Capability | Details/Specifications |

|---|---|

| Material Compatibility | Stainless Steel, Aluminum, Tool Steel, Copper, Ceramics, Carbides |

| Grinding Methods | Surface Grinding, Cylindrical Grinding, Centerless Grinding, Internal Grinding |

| Tolerance | ± 0.0001 inches (0.0025 mm) or better (specific to material and grinding method) |

| Maximum Workpiece Size | Length: 24 inches (600 mm) Width: 10 inches (250 mm) Diameter: 8 inches (200 mm) for cylindrical grinding |

| Surface Finish | Achievable down to Ra 0.1 µm or better (based on material and grinding method) |

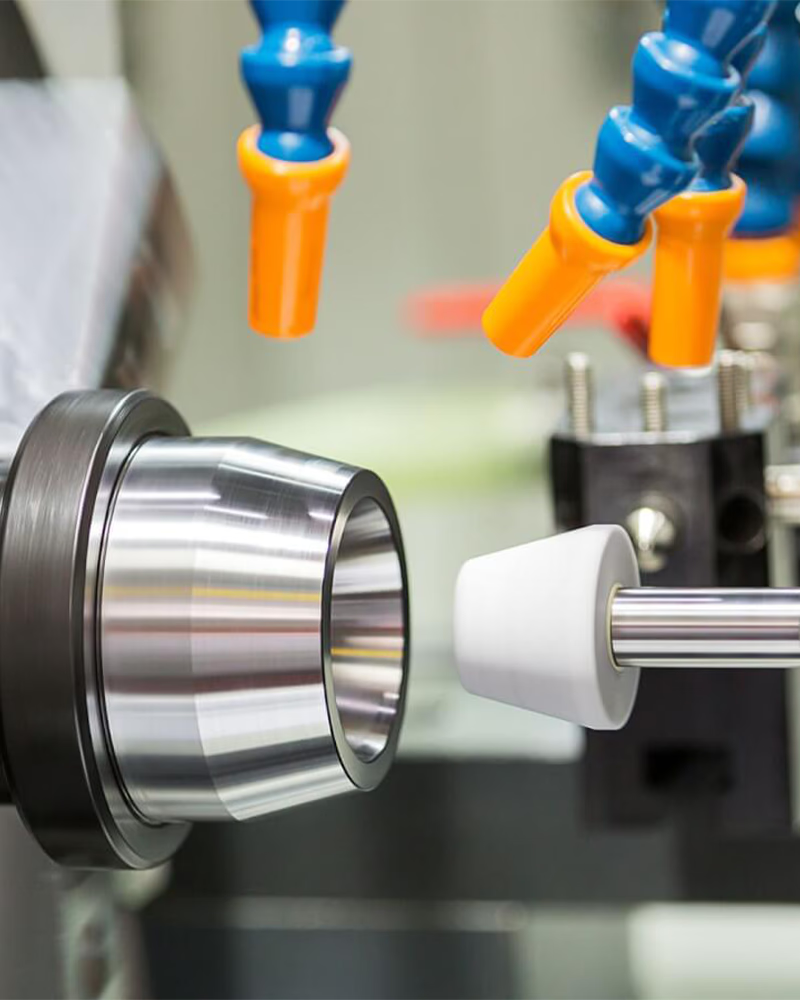

CNC Turning Service

| Capability | Details/Specifications |

|---|---|

| Material Compatibility | Stainless Steel, Aluminum, Tool Steel, Copper, Brass, Titanium, Plastics |

| Turning Operations | External & Internal Turning, Facing, Taper Turning, Boring, Drilling, Threading |

| Tolerance | ± 0.0005 inches (0.0127 mm) or better (specific to material and operation) |

| Maximum Workpiece Diameter | 20 inches (508 mm) or specific to machine capability |

| Maximum Workpiece Length | 60 inches (1524 mm) or specific to machine capability |

| Axis | 2-axis, 3-axis, multi-axis turning capability |

| Bar Feeding Diameter | Up to 3 inches (76 mm) or machine-specific |

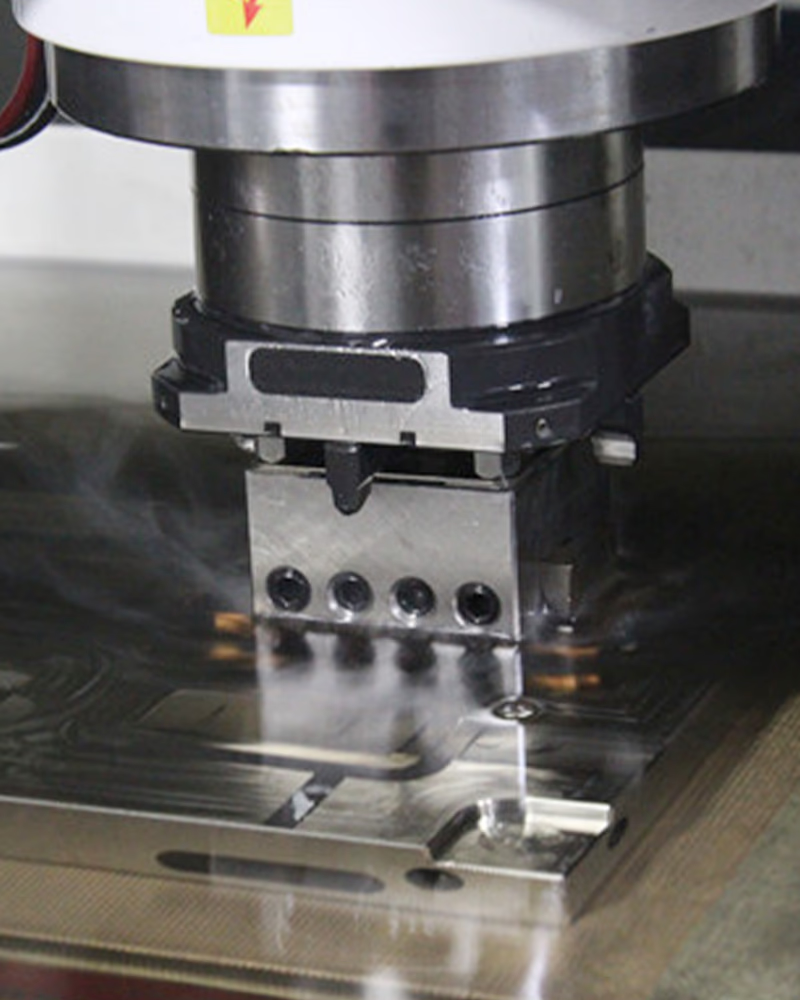

CNC Milling Service

| Capability | Details/Specifications |

|---|---|

| Material Compatibility | Stainless Steel, Aluminum, Tool Steel, Copper, Brass, Titanium, Plastics |

| Milling Operations | Face Milling, Profile Milling, Pocket Milling, Complex Surface Milling, Drilling, Boring |

| Tolerance | ± 0.0005 inches (0.0127 mm) or better (specific to material and operation) |

| Maximum Workpiece Size | X: 40 inches (1016 mm) Y: 20 inches (508 mm) Z: 25 inches (635 mm) or specific to machine capacity |

| Axis | 2-axis, 3-axis, multi-axis turning capability |

| Bar Feeding Diameter | Up to 3 inches (76 mm) or machine-specific |

Arapidtools Precision Machining Solutions

PROTOTYPING

Rapid Prototyping

- Capability: 20-500

- Lead Time: 10 business days

PRODUCTION

Low and High-Volume Production

- Capacity: 1000+

- Lead Time: 15 business days

Precision CNC Machining Tolerances

| Typical Tolerance (mm) | Best Possible Tolerance (mm) | Notes | |

|---|---|---|---|

| EDM (Electrical Discharge Machining) | ±0.015 | ±0.005 | Tolerance can be affected by electrode wear. |

| Grinding | ±0.005 | ±0.001 | Surface finish is typically smoother with grinding. |

| CNC Turning | ±0.025 | ±0.010 | Finish can impact tolerance. |

| CNC Milling | ±0.025 | ±0.005 | Precision can vary based on tool type and material. |

Materials & Surface Finishes

Materials

We provide a wide range of materials, including metals, plastics, and composites.

Surface Finish

We offer superior surface finishes that enhance part durability and aesthetics for applications requiring smooth or textured surfaces.

Advantages

Advantages of Precision Machining

Precision machining offers numerous advantages for producing high-accuracy parts, making it essential for various industries.

- High Accuracy: Precision machining ensures that each part is produced with extremely tight tolerances, meeting exact specifications, which is crucial for intricate applications like aerospace and medical devices.

- Consistency: It guarantees unmatched consistency, even in large production volumes, with each part remaining identical, reducing errors and defects.

- Material Versatility: This method works with a wide range of materials, including metals, plastics, and composites, allowing for the selection of the ideal material based on specific requirements.

- Complex Geometries: Advanced CNC machines enable the creation of complex shapes that are difficult or impossible to achieve manually, vital for developing innovative products.

- Reduced Waste: The accuracy of precision machining minimizes material wastage, saving on raw materials and reducing environmental impact.

- Speed: Modern precision machining is highly automated, leading to faster production times and quicker project turnarounds, meeting market demands efficiently.

Applications

Applications of Precision Machining

Precision machining is vital in producing specialized parts across various industries:

- Engine Components: Precision machining is crucial for manufacturing engine parts like pistons and crankshafts in the automotive and aerospace sectors, where exact dimensions are essential for optimal performance.

- Electronics Parts: This process is key in creating components such as connectors and pins for electronic devices, ensuring precise measurements for functionality and compact assembly.

- Medical Implants: Precision machining is used to produce surgical implants, including hip and knee replacements, where tight tolerances and smooth finishes are critical for compatibility with human tissue.

- Aerospace Fasteners: It involves crafting high-strength bolts and screws designed to withstand extreme environmental conditions in aerospace applications.

- Tool and Die Making: Precision machining is fundamental in creating molds and dies, essential for consistent and quality parts in mass production settings.

Precision Machining FAQs

When do I need to choose precision machining?

Can precision provide tight tolerance?

Yes, precision machining is specifically designed to provide tight tolerances. This technique can achieve tolerances as narrow as +/- 0.0005 inches, which is essential for creating highly accurate and consistent parts. The ability to maintain such precise measurements is crucial in applications where even the smallest deviation can lead to significant issues, such as in aerospace components or medical devices. Advanced CNC machines, which are commonly used in precision machining, are capable of producing parts with these strict specifications reliably.

How can I get quote for my CNC precision machining project?

To get a quote for a CNC precision machining project, you should prepare detailed information about your part or assembly, including CAD drawings, material specifications, and quantity needed. You will also need to specify the tolerances required and any additional post-processing like finishing or heat treating. With this information, go to Arapidtools online platform where you can upload your design files and receive a pricing estimate quickly.