Overmolding Service

High-quality custom overmolding services for both prototypes and on-demand production parts, with rapid tooling production in as fast as 2 weeks.

Start A New Overmolding Quote

STEP | STP | SLDPRT | IPT | PRT | SAT files

- All uploads are secure and confidential.

What is Overmolding?

Overmolding is an advanced plastic injection molding technique that combines two or more thermoplastic materials into a single, unified part. The process starts by injecting the first thermoplastic, known as the substrate, which forms the core structure of the product. Subsequently, a second material, called the overmold, is injected either around or onto the substrate. As the materials cool, they bond together. This technique enhances the durability, functionality, and aesthetics of products. It is commonly used in high – volume production for industries that require high – performance parts, such as automotive, medical devices, and electronics.

At our company, we specialize in custom plastic overmolding to enhance the functionality and visual appeal of your components. Our expert team and advanced technology ensure seamless bonding between materials, guaranteeing top – notch quality results.

Contact us today to get a detailed quote for custom overmolded parts tailored to your needs.

Overmolding Process

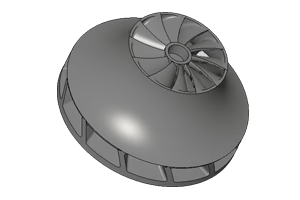

Plastic over Plastic

Crucial for mass production, this process involves machining and assembling durable molds from steel or aluminum to ensure precise and repeatable part geometries.

Rubber Over Plastic

Overmolding enhances product functionality and aesthetics by combining different materials into a single part, adding features such as soft grips and multi-color designs for improved usability.

Plastic Over Metal

Insert molding enhances strength and reduces assembly time by integrating metal or other materials directly into plastic parts during the molding process, creating components with embedded features.

Rubber Over Metal

Insert molding integrates metal or other materials into plastic parts during the molding process, enhancing component strength and reducing assembly time by incorporating embedded features directly into the design.

Overmolding Tooling Solutions

PROTOTYPING

Rapid Tooling

Quickly receive design feedback and validation with top-quality prototype tooling. Produce small batches of plastic molded parts with precise injection molding prototypes. We specialize in creating prototype molds within days, allowing you to conduct functional tests and gauge market interest efficiently.

PRODUCTION

Production Tooling

We craft high-quality production molds designed for high-volume plastic part manufacturing. Using robust, durable tool steel, our production tooling is built to produce hundreds of thousands of parts. We can customize materials and construction methods to meet your specific needs.

materials

Materials for Overmolding

We offer a wide range of thermoplastic and thermoset materials, each selected for its performance characteristics and suitability for different applications.

Plastics

ABS is strong, durable, and offers good resistance to heat and impact. It’s preferred for automotive components and consumer goods.

- ABS Beige(Natural)

- ABS Black

- ABS Black Antistatic

- ABS Milky White

- ABS+PC Black

- ABS+PC White

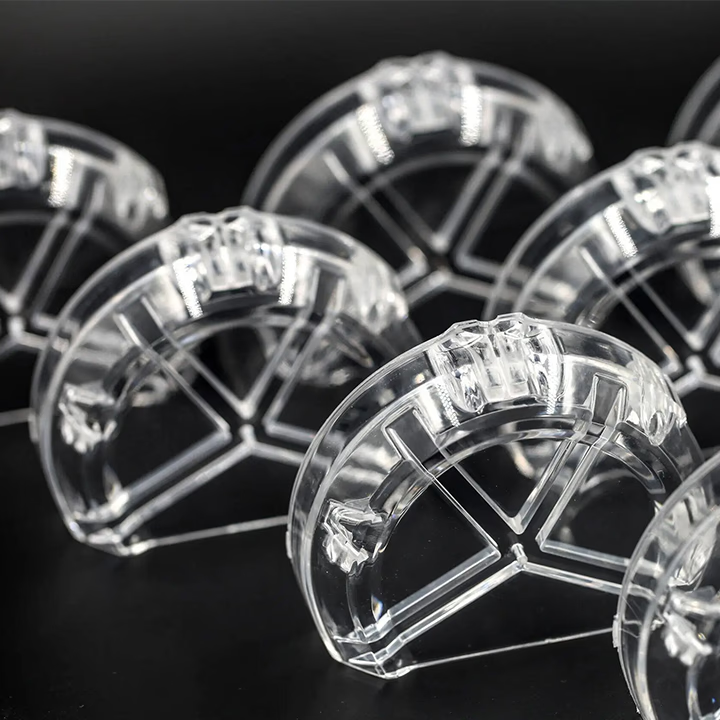

Polycarbonate is extremely durable and has high impact resistance, along with excellent clarity, used for bullet-proof glass and protective gear.

- PC Black

- PC Transparent

- PC White

- PC Yellowish White

- PC+GF30 Black

PMMA, or acrylic, is known for its crystal clarity and weather resistance, making it ideal for outdoor fixtures and display cases.

- PMMA Black

- PMMA Transparent

- PMMA White

POM is strong, with a low friction surface and good dimensional stability, perfect for precision parts in mechanical applications.

- Dark brown (coffee) POM 100AF

- POM Black

- POM Blue

- POM White

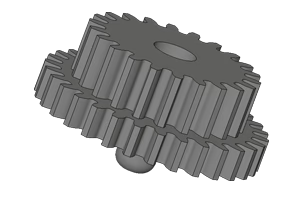

Nylon is versatile, strong, and wears well against friction, commonly used for gears, bearings, and other wear-resistant surfaces.

- PA(Nylon) Blue

- PA6 (Nylon)+GF15 Black

- PA6 (Nylon)+GF30 Black

- PA66 (Nylon) Beige(Natural)

- PA66 (Nylon) Black

Polyethylene is lightweight and has high resistance to impact, widely used in packaging and containers.

- PE Black

- PE White

PEEK is renowned for its high temperature resistance and strength, often used in aerospace and medical implant manufacturing.

- PEEK Beige(Natural)

- PEEK Black

Polypropylene is tough, has excellent chemical resistance, and is used for automotive parts, containers, and in packaging.

- PP Black

- PP White

- PP+GF30 Black

HDPE is known for its high strength-to-density ratio, resistance to impacts, and is used in making bottles and corrosion-resistant piping.

- HDPE Black

- HDPE White

HIPS is easy to machine and offers good dimensional stability and impact resistance, suitable for prototyping and modeling.

- HIPS Board White

LDPE is soft, flexible, and used in applications where heat sealing is required, such as in tubing and plastic bags.

- LDPE White

PBT is a strong, rigid plastic that is heat resistant and commonly used in electrical components and casings.

- PBT Black

- PBT Milky White(Natural)

Like High-Performance Plastics, Engineering Plastics, Industrial Plastics, Biocompatible Materials, Food Safe Plastics, and Other Modified Thermoplastics. There are many other plastic or resin materials for different applications. Whether it’s on our material list or not, we could source them from a certified supplier for your project.

Overmolding Capabilities

| Standards | Description |

|---|---|

| Maximum Part Size | 200×400×100mm (7.87×15.75×3.94 in.) |

| Minimum Part Size | 2×2×2mm (0.08×0.08×0.08 in.) |

| Substrate Wall Thickness | 0.5 – 3mm (0.20 – 0.12 in.) |

| Tolerance | ±0.025mm (±0.00098 in.) |

| Radii | 0.1mm (0.0039 in.) |

| Depth | 100mm from the parting line (3.94 in. from the parting line) |

| Mold Validation | Provide T0, T1, T2 samples before mass production |

| Inspection and Certification Options | First Article Inspection, ISO 9001, ISO 13485 |

| Lead Time | From mold making to sample delivery: 15 – 35 business days |

Advantages of Overmolding

- Improved Design and Custom Plastic Part Manufacturing: Overmolding capabilities ensure the production of custom plastic - plastic or metal - plastic product combinations with high - dimensional accuracy.

- Better Product Performance: Overmolded parts have excellent quality due to the advantages of using two materials in various applications.

- Increased Shelf and Aesthetic Appeal: The overmolding process can be optimized with a variety of materials and surface treatment processes to improve the aesthetic quality of the product.

- Better Shock Absorption and Overall Durability: Overmolding also offers improved shock absorption due to the addition of plastic resin, ensuring a longer shelf life and excellent impact resistance.

- Lower Production Costs: Since overmolding eliminates the post - assembly phase of production, it speeds up the production process and reduces overall manufacturing costs.

Applications of Overmolding

The injection overmolding process is compatible with a wide range of materials, from plastics to metals. Depending on your requirements, this process helps produce custom prototypes and production parts for various applications. Many industries find great value in overmolding services.

- Surgical Instruments: Overmolding meets the stringent precision and safety standards of the medical industry. It allows for the efficient creation of surgical devices, equipment housings, catheters, syringes, and more by combining plastics and metals.

- Electrical Applications: The use of thermoplastic elastomers in overmolding is ideal for creating durable electrical components. Custom overmolded parts, such as electrical outlet covers and gaskets, are designed to withstand harsh conditions, enhancing their longevity.

- Hardware Tools: Overmolding is excellent for manufacturing tools like pliers, screwdrivers, hammers, wrenches, and pocket knives. The process improves grip and overall usability, making these tools more efficient in their applications.

- Household Items: Overmolding enhances the functional performance of household items, improving grip, cleanliness, and ease of use. It also provides benefits like vibration dampening and chemical resistance, making it ideal for kitchen utensils, toothbrushes, pens, shampoo bottles, and more.

Let's Start A New Project Today