Custom Injection Molding Services

Get free injection molding quotes and expert feedback for rapid molds, production tooling, and custom molded prototypes within one day. Choose from over 100 thermoplastic and thermoset materials, ensuring the perfect match for your project. Our services are backed by certifications including ISO 9001:2015, ISO 13485, ISO 14001:2015, and IATF 16949:2016, guaranteeing high-quality results for all your injection molding needs.

Start A New Injection Molding Quote

STEP | STP | SLDPRT | IPT | PRT | SAT files

- All uploads are secure and confidential.

Plastic Injection Molding Services for Custom Parts

Our injection molding process is optimized to handle a wide range of projects, from plastic prototypes to full-scale production parts, with a standard lead time of 15 business days. For projects requiring quicker turnaround, our quick-turn injection mold services provide an ideal solution. Understanding the complexities involved in injection molding, we offer expert consultation to help transition seamlessly from design to production. Based in China, our extensive manufacturing network is equipped with injection molding machines ranging from 90 to 830 tons, enabling us to produce parts of various sizes and complexities efficiently.

Injection Mold Tooling

Crucial for mass production, injection molding involves machining and assembling durable molds from steel or aluminum, ensuring precise and repeatable part geometries.

Overmolding

Overmolding enhances product functionality and aesthetics by fusing different materials into a single part, incorporating features such as soft grips and multi-color designs to improve usability.

Insert Molding

Insert molding integrates metal or other materials into plastic parts during the molding process, enhancing strength and reducing assembly time by creating components with embedde.

LSR Molding

Liquid Silicone Rubber molding is a versatile and advanced manufacturing process that excels in producing high-quality, intricate parts with exceptional durability. This technique involves injecting liquid silicone rubber into precision molds, which then cure to form flexible, resilient components.

RapidTools Injection Molding Solutions

RapidTools’s custom injection molding services seamlessly bridge the gap from prototyping to high-quality production. Our solutions accelerate product development cycles, ensuring superior injection molded parts and streamlining your path from concept to market. Experience unmatched efficiency and quality at every project phase with RapidTools.

PROTOTYPING

Rapid Prototyping

Address time-to-market needs with our flexible, cost-effective solutions for rapid prototyping and iterative development. Refine your designs efficiently before full-scale production to stay ahead in the market.

- Utilize aluminum or steel molds, which are perfect for rigorous testing and iterative processes.

- Typically single cavity, allowing for precise control during the prototype phase.

- Efficiently produce anything from a single unit to small batches (up to 2,000 units), facilitating quick market testing and design validation.

PRODUCTION

High-Volume Production

Support large-scale manufacturing with on-demand production capabilities. Overcome common production challenges effectively to meet high-volume demands.

- Durable steel molds designed for high repeatability across extensive production runs.

- Available in single or multi-cavity configurations to optimize productivity and cost-efficiency.

- Ability to scale production seamlessly to meet large order demands, ensuring consistent quality and timely delivery.

Injection Molding Manufacturing Network

Equipped with over 50 advanced machines capable of handling up to 830 tons, our network seamlessly manages projects from prototypes to full-scale production. Each engagement begins with a detailed injection mold quote to establish clear expectations. Our project managers provide comprehensive manufacturing analysis and consultative design services to optimize products for cost-effectiveness and functionality. The process concludes with detailed quality reports, ensuring all components meet and exceed industry standards.

materials

Injection Molding Materials

We offer a wide range of thermoplastic and thermoset materials, carefully selected for their performance characteristics and suitability for various applications.

Plastics

ABS is strong, durable, and offers good resistance to heat and impact. It’s preferred for automotive components and consumer goods.

- ABS Beige(Natural)

- ABS Black

- ABS Black Antistatic

- ABS Milky White

- ABS+PC Black

- ABS+PC White

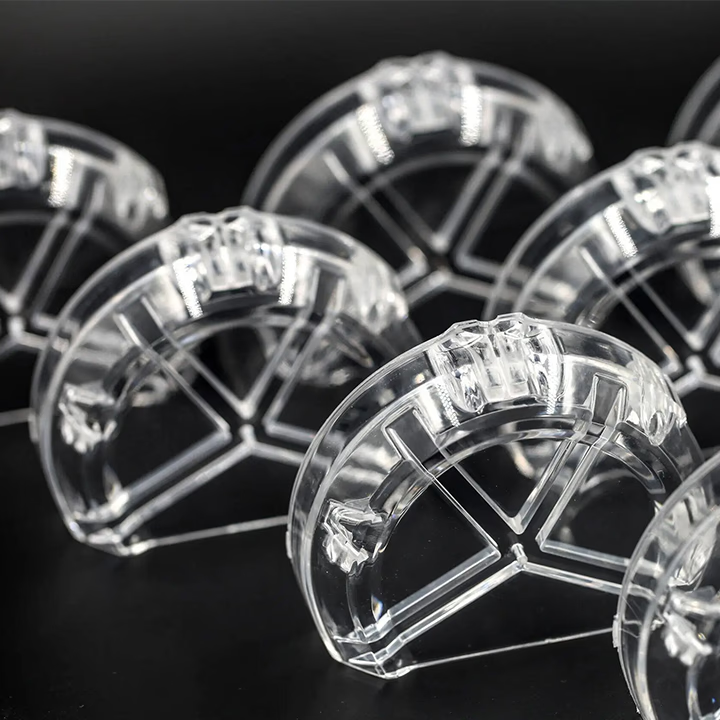

Polycarbonate is extremely durable and has high impact resistance, along with excellent clarity, used for bullet-proof glass and protective gear.

- PC Black

- PC Transparent

- PC White

- PC Yellowish White

- PC+GF30 Black

PMMA, or acrylic, is known for its crystal clarity and weather resistance, making it ideal for outdoor fixtures and display cases.

- PMMA Black

- PMMA Transparent

- PMMA White

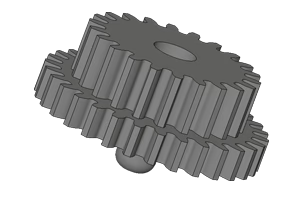

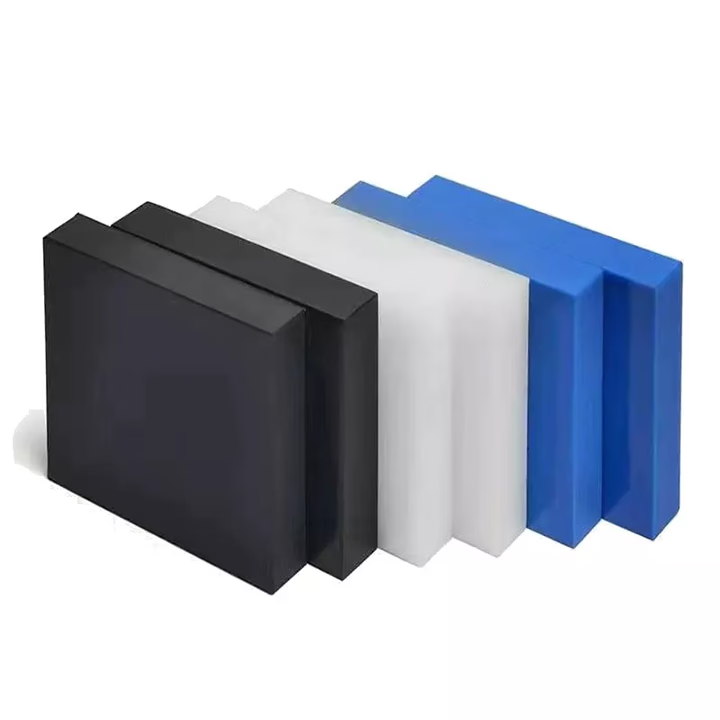

POM is strong, with a low friction surface and good dimensional stability, perfect for precision parts in mechanical applications.

- Dark brown (coffee) POM 100AF

- POM Black

- POM Blue

- POM White

Nylon is versatile, strong, and wears well against friction, commonly used for gears, bearings, and other wear-resistant surfaces.

- PA(Nylon) Blue

- PA6 (Nylon)+GF15 Black

- PA6 (Nylon)+GF30 Black

- PA66 (Nylon) Beige(Natural)

- PA66 (Nylon) Black

Polyethylene is lightweight and has high resistance to impact, widely used in packaging and containers.

- PE Black

- PE White

PEEK is renowned for its high temperature resistance and strength, often used in aerospace and medical implant manufacturing.

- PEEK Beige(Natural)

- PEEK Black

Polypropylene is tough, has excellent chemical resistance, and is used for automotive parts, containers, and in packaging.

- PP Black

- PP White

- PP+GF30 Black

HDPE is known for its high strength-to-density ratio, resistance to impacts, and is used in making bottles and corrosion-resistant piping.

- HDPE Black

- HDPE White

HIPS is easy to machine and offers good dimensional stability and impact resistance, suitable for prototyping and modeling.

- HIPS Board White

LDPE is soft, flexible, and used in applications where heat sealing is required, such as in tubing and plastic bags.

- LDPE White

PBT is a strong, rigid plastic that is heat resistant and commonly used in electrical components and casings.

- PBT Black

- PBT Milky White(Natural)

Like High-Performance Plastics, Engineering Plastics, Industrial Plastics, Biocompatible Materials, Food Safe Plastics, and Other Modified Thermoplastics. There are many other plastic or resin materials for different applications. Whether it’s on our material list or not, we could source them from a certified supplier for your project.

Injection Mold Surface Finishes

Our expertise also extends to providing SPI finishes for plastic injection molds that enhance the aesthetics and functionality of your plastic molded parts.

SPI A

| Finishing Look | High Gloss |

|---|---|

| SPI Finish Grades | SPI A1, A2, A3 |

| Surface Roughness Ra (μm) | SPI A1: 0.012 to 0.025 SPI A2: 0.012 to 0.025 SPI A3: 0.05 to 0.10 |

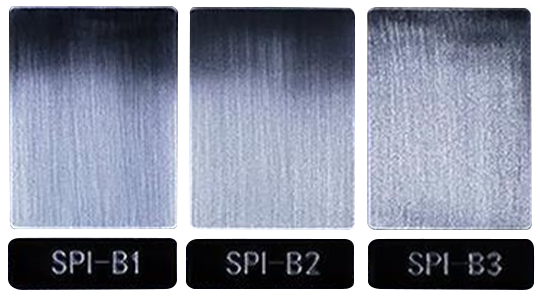

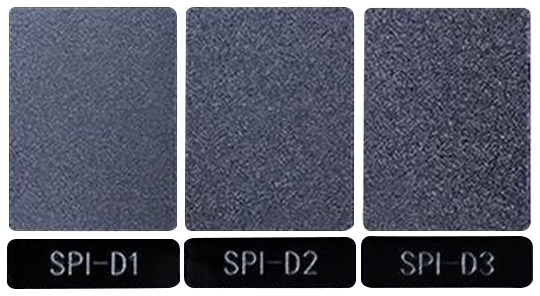

SPI B

| Finishing Look | Semi Gloss |

|---|---|

| SPI Finish Grades | SPI B1, B2, B3 |

| Surface Roughness Ra (μm) | SPI B1: 0.05 to 0.10 SPI B2: 0.10 to 0.15 SPI B3: 0.28 to 0.32 |

SPI C

| Finishing Look | Low Gloss |

|---|---|

| SPI Finish Grades | SPI C1, C2, C3 |

| Surface Roughness Ra (μm) | SPI C1: 0.35 to 0.40 SPI C2: 0.45 to 0.55 SPI C3: 0.63 to 0.70 |

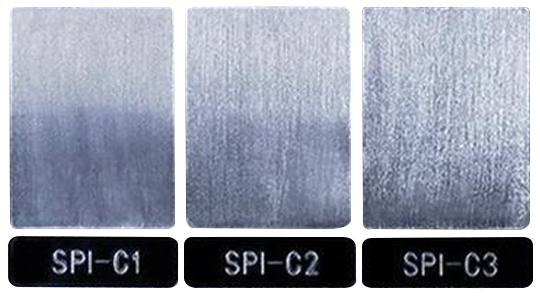

SPI D

| Finishing Look | Matte |

|---|---|

| SPI Finish Grades | SPI D1, D2, D3 |

| Surface Roughness Ra (μm) | SPI D1: 0.80 to 1.00 SPI D2: 1.00 to 2.80 SPI D3: 3.20 to 18.0 |

Injection Molding Capabilities

| Standards | Description |

|---|---|

| Maximum Part Size | 1200×1000×500 mm |

| Manimum Part Size | 5×5×5 mm |

| Part to Part Repeatability | +/- 0.1 mm |

| Mold Cavities | Single-cavity molds, multi-cavity molds, family molds |

| Available Mold Types | Steel and aluminum molds. Production levels below 1000, 5000, 30000, and over 100000 uses |

| Mold Cavity Tolerances | +/- 0.05 mm |

| Secondary Operations | Mold texturing, pad printing, laser engraving, threaded inserts, and basic assembly |

| Undercuts | Y-type, L-type undercuts |

| Wall Thickness | 0.5 mm to 5 mm |

| Draft | 0.5° to 2° |

| RIbs/Gussets | 0.5 mm to 3 mm thick |

| Bosses | Diameter 3 mm to 10 mm |

| Lead Time | Most orders can be completed within 15 working days |

Injection Molding for Various Industries

With RapidTools, you can benefit from custom injection molding that seamlessly adapts to the diverse requirements of different industry sectors, ensuring optimal results for every project.

Automotive

Our low-volume manufacturing services is the ideal manufacturing solution for on demand automotive parts.

Aerospace

The durability and precision that our precison manufacturing services provide meets the sophisticated needs the different phases of the aerospace industry required.

Consumer Products

Strong partnerships with leading consumer manufacturers help us accelerate the prototyping process and improve the consumer goods industry.

Medical Devices

Medical supplies manufacturers, tech startups, and research labs benefit significantly from the prototyping solutions we provide.

Robotics

Our industrial-grade robotics prototyping and parts manufacturing services aid in the continuous evolution of the robotics market.

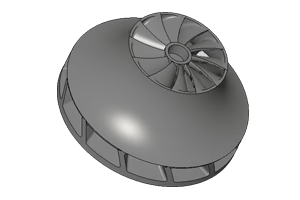

Applications of Injection Molding

Injection molding is a critical process for producing a wide range of components with precision and efficiency. Key applications include:

- Gears: High-tolerance, durable gears for mechanical and electronic devices.

- Housings: Robust housings for consumer electronics, automotive components, and industrial machines.

- Enclosures: Protective enclosures for electronics, ensuring precise fit and safeguarding internal components.

- Handles: Ergonomic, durable handles for tools, appliances, and consumer products.

- Caps and Closures: Efficient manufacturing of caps and closures for bottles and containers, ensuring tight seals and product integrity.

- Connectors: Small, intricate connectors for electrical and electronic applications, where precision is crucial.

Advantages

Advantages of Injection Molding

Injection molding is a preferred method for efficiently producing complex parts with high consistency. Key advantages include:

- High Repeatability: Ensures uniform product quality across large production volumes.

- Material Diversity: Supports a wide range of materials, enabling optimal selection based on properties like durability and flexibility.

- Cost-Effectiveness: Ideal for mass production, with initial mold and setup costs offset by low per-unit expenses at high volumes.

- Complex Designs: Capable of producing intricate parts, minimizing the need for additional assembly.

- Multi-Material Integration: Techniques like overmolding enable the incorporation of multiple materials in a single part, enhancing both functionality and aesthetics.

Disadvantages

Disadvantagess of Injection Molding

Injection molding is widely used for plastic parts, but it comes with some disadvantages:

- High Initial Costs: Expensive machinery and molds make setup costly, particularly for small-scale productions.

- Limited Design Changes: Altering a mold's design can be costly and time-consuming, reducing flexibility.

- Material Restrictions: Primarily used with certain plastics, limiting material options based on project needs.

- Environmental Concerns: Often involves non-biodegradable plastics, raising disposal and environmental issues unless managed properly.

- Waste Production: Excess plastic can create waste, though some may be recycled, adding complexity to the process.

Injection Molding FAQs

Is injection molding a good option for prototyping?

Injection molding could absolutely be used for prototyping, but it depends on the project requirements. Typically, for projects that require less than 10 prototypes, injection molding may not be the most cost-effective option. We are happy to meet with you to discuss your needs and help determine if injection molding is the correct process for you.

What is the minimum order quantity for injection molding?

Does Arapidtools provide a no-obligations estimate for my injection molding project?

Once I have a mold, can I reorder from it?

Does Arapidtools charge an inventory fee on my molds?

Does Arapidtools provide DFM on my part design before I place an order?

We do! Not only are you able to access your DFM through the Fictiv platform, but you will receive 3D visualization of the DFM feedback and be able to comment on, annotate, and discuss this feedback with a Fictiv technical project lead. All of this happens before you place your order.

Does Arapidtools charge for DFM feedback?

Does Arapidtools build quick turn Aluminum molds?

At what quantity is it worth it for me to move from 3D printing my parts to injection molding them?

A part manufactured through 3D printing is orders of magnitude more expensive than the same part manufactured through injection molding, assuming the design is a fit for injection molding. As long as you produce enough of that part to offset the mold cost, it would be worth it to pursue injection molding. Arapidtools provides you with DFM on your design and options for mold architecture to give you the best cost-benefit balance. Request an injection molding quote for your 3D-printed part design to get a no-obligation quotation and DFM and assess your options at no cost to you. It is recommended that you get an expert involved early on in the design process if you intend to use injection molding for production. Many customers invest significant time in creating 3D-printed prototypes and making revisions without taking into account the specific manufacturing constraints associated with injection molding. This oversight can lead to wasted resources, both in terms of money and time. By providing Design for Manufacturability (DFM) guidance tailored to injection molding, Arapidtools can help you avoid such pitfalls, resulting in significant savings in time and costs.

What DFM analyses does Arapidtools provide?

Does Arapidtools perform mold flow analysis before building the molds?

How long will it take to make injection molding tooling?

How long does it take to make molded parts?

How does Arapidtools protect my intellectual property?

Let's Start A New Project Today