5 Axis CNC Machining Services

Achieve high precision and intricate geometries with our 5-axis CNC machining services. We deliver parts with tolerances as tight as 0.01mm. Get instant online quotes for your CNC projects

Start A New CNC Quote

STEP | STP | SLDPRT | IPT | PRT | SAT files

- All uploads are secure and confidential.

5 Axis Machining With Arapidtools

Arapidtools’ 5-axis machining services provide unmatched speed and flexibility. With a wide array of advanced 5-axis CNC machines and various materials, RapidDirect can deliver superior machined parts.

Our skilled team and robust manufacturing capabilities enable us to swiftly design and fabricate complex, time-sensitive components. Utilizing world-class equipment and expertise, Arapidtools employs two exceptional setups to ensure precise, intricate parts.

What is 5-axis Machining?

5-axis CNC machining is a cutting-edge manufacturing process that enables the cutting tool to move across five different axes simultaneously. This capability is crucial for producing complex, high-precision parts more efficiently and with fewer setups. Industries such as aerospace, automotive, and medical device manufacturing depend on 5-axis machining services for intricate components that demand exceptional accuracy.

5-axis VS. 3-axis Machining

In CNC machining, the choice between 3-axis and 5-axis systems significantly impacts production capabilities. 3-axis machining operates along the X, Y, and Z axes, making it suitable for simpler parts with flat surfaces. It is commonly used in industries like automotive, construction, and aerospace due to its efficiency and cost-effectiveness.

Conversely, 5-axis machining introduces two rotational axes, allowing the tool to cut from multiple angles. This capability is ideal for producing highly intricate parts with complex geometries, making it the preferred choice in fields such as aerospace, medical, and advanced automotive manufacturing, where precision and tight tolerances are essential.

While 5-axis systems typically involve higher initial costs, they enhance production efficiency by minimizing the need for multiple setups and reducing the likelihood of human error. Ultimately, 3-axis machines are best for basic designs, whereas 5-axis machines excel at creating complex components that require greater accuracy.

Materials for Custom 5-axis CNC Machining

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Metals

Aluminum is lightweight yet strong, with excellent machinability and corrosion resistance. Ideal for aerospace and automotive parts.

Alloys

- Aluminum 6061, 6061-T6

- Aluminum 2024

- Aluminum 5052

- Aluminum 5083

- Aluminum 6063

- Aluminum 6082

- Aluminum 7075, 7075-T6

- Aluminum ADC12 (A380)

Copper is known for its superior electrical conductivity and thermal properties, making it perfect for electrical components and heat exchangers.

Alloys

- Copper C101(T2)

- Copper C103(T1)

- Copper C103(TU2)

- Copper C110(TU0)

- Beryllium Copper

Brass is durable and has a low friction coefficient, which makes it suitable for fittings, tools, and musical instruments that require precision.

Alloys

- Brass C27400

- Brass C28000

- Brass C36000

Bronze is highly resistant to corrosion and metal fatigue, favored for bearings, bushings, and marine hardware.

Alloys

- Tin Bronze

Steel is an alloy with high tensile strength and durability, commonly used in construction and automotive industries for its robustness.

Alloys

- Steel 1018, 1020, 1025, 1045, 1215, 4130, 4140, 4340, 5140, A36

- Die steel

- Alloy steel

- Chisel tool steel

- Spring steel

- High speed steel

- Cold rolled steel

- Bearing steel

- SPCC

Stainless steel is renowned for its corrosion resistance, making it a prime choice for medical devices and food processing equipment.

Alloys

- Stainless Steel SUS201

- Stainless Steel SUS303

- Stainless Steel SUS 304

- Stainless Steel SUS316

- Stainless Steel SUS316L

- Stainless Steel SUS420

- Stainless Steel SUS430

- Stainless Steel SUS431

- Stainless Steel SUS440C

- Stainless Steel SUS630/17-4PH

- Stainless Steel AISI 304

Magnesium is the lightest structural metal, offering high strength-to-weight ratios, perfect for automotive and aerospace applications where weight is critical.

Alloys

- Magnesium Alloy AZ31B

- Magnesium Alloy AZ91D

Titanium boasts the highest strength-to-density ratio among metals, highly resistant to corrosion and fatigue, ideal for aerospace, medical, and marine applications.

Alloys

- Titanium Alloy TA1

- Titanium Alloy TA2

- Titanium Alloy TC4/Ti-6Al 4V

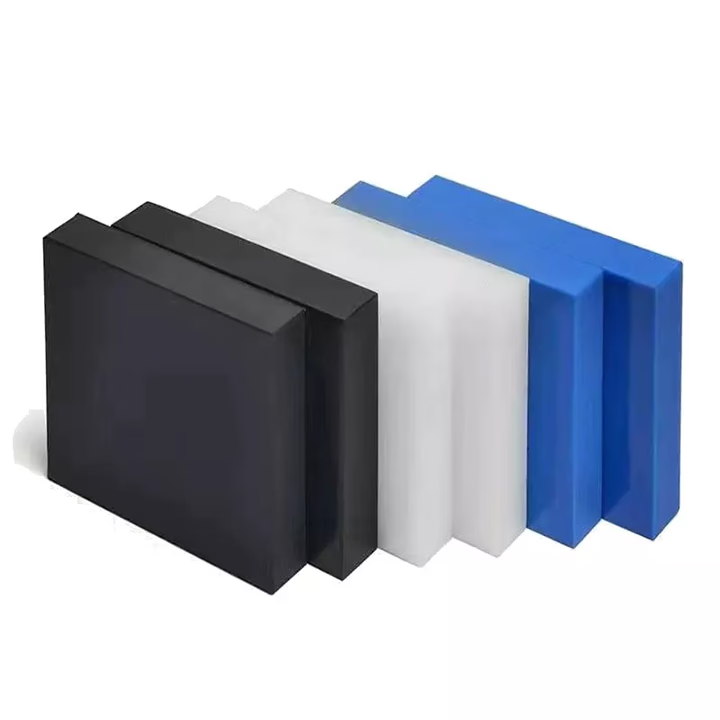

Plastics

ABS is strong, durable, and offers good resistance to heat and impact. It’s preferred for automotive components and consumer goods.

- ABS Beige(Natural)

- ABS Black

- ABS Black Antistatic

- ABS Milky White

- ABS+PC Black

- ABS+PC White

Polycarbonate is extremely durable and has high impact resistance, along with excellent clarity, used for bullet-proof glass and protective gear.

- PC Black

- PC Transparent

- PC White

- PC Yellowish White

- PC+GF30 Black

PMMA, or acrylic, is known for its crystal clarity and weather resistance, making it ideal for outdoor fixtures and display cases.

- PMMA Black

- PMMA Transparent

- PMMA White

POM is strong, with a low friction surface and good dimensional stability, perfect for precision parts in mechanical applications.

- Dark brown (coffee) POM 100AF

- POM Black

- POM Blue

- POM White

Nylon is versatile, strong, and wears well against friction, commonly used for gears, bearings, and other wear-resistant surfaces.

- PA(Nylon) Blue

- PA6 (Nylon)+GF15 Black

- PA6 (Nylon)+GF30 Black

- PA66 (Nylon) Beige(Natural)

- PA66 (Nylon) Black

Polyethylene is lightweight and has high resistance to impact, widely used in packaging and containers.

- PE Black

- PE White

PEEK is renowned for its high temperature resistance and strength, often used in aerospace and medical implant manufacturing.

- PEEK Beige(Natural)

- PEEK Black

Polypropylene is tough, has excellent chemical resistance, and is used for automotive parts, containers, and in packaging.

- PP Black

- PP White

- PP+GF30 Black

HDPE is known for its high strength-to-density ratio, resistance to impacts, and is used in making bottles and corrosion-resistant piping.

- HDPE Black

- HDPE White

HIPS is easy to machine and offers good dimensional stability and impact resistance, suitable for prototyping and modeling.

- HIPS Board White

LDPE is soft, flexible, and used in applications where heat sealing is required, such as in tubing and plastic bags.

- LDPE White

PBT is a strong, rigid plastic that is heat resistant and commonly used in electrical components and casings.

- PBT Black

- PBT Milky White(Natural)

PPA offers high heat resistance and stiffness, ideal for automotive and electrical applications that require durability at high temperatures.

PAI has exceptional thermal and chemical stability, used in high-performance parts in aerospace and automotive sectors.

- PAI Brown

For Example: High Performance Plastics, Engineering Plastics, Industrial Plastics, Biocompatible Materials, Food Safe Plastics, and Other Modified Thermoplastics.

Surface Finishes for 5 Axis CNC Machining

Arapidtools offers a variety of surface finish options that can significantly enhance the surface quality of your 5-axis machined parts. These finishes not only improve the appearance, surface roughness, hardness, and corrosion resistance of the components, but they also effectively conceal visible tool marks on the surfaces of the products.

As Machined

Anodizing

Anodizing increases corrosion resistance and wear properties, while allowing for color dyeing, ideal for aluminum parts.

Polishing

Polishing achieves a high gloss finish, reducing surface roughness and enhancing the aesthetic appeal of metals.

Sand Blasting

Sand blasting uses pressurized sand or other media to clean and texture the surface, creating a uniform, matte finish.

Tumbling

Electropolish

Electropolish is a chemical process that smooths and brightens surfaces while improving corrosion resistance.

Alodine

Alodine coating provides corrosion protection and improves paint adhesion, mainly used on aluminum surfaces.

Heat Treatment

Brushed Finish

A brushed finish creates a unidirectional satin texture, reducing the visibility of marks and scratches on the surface.

Powder Coating

Powder coating applies a thick, wear-resistant layer with excellent color and texture options, suitable for a variety of surfaces.

Electroplating

Electroplating bonds a thin metal layer onto parts, improving wear resistance, corrosion resistance, and surface conductivity.

Black Oxidize

5-Axis CNC Machining Capabilities

Our ISO 9001 certification shows that we fabricate 5-axis milled parts to meet the tightest tolerance requirements. Our standard tolerance for CNC-milled plastics is ISO-2768-m and ISO-2768-f for metals. Get high-quality and precise complex parts with top-notch dimensional stability.

| Description | |

|---|---|

| Maximum Part Size | 4000×1500×600 mm |

| Minimum Part Size | 5 x 5 x 5 mm |

| General Tolerances | Within ±0.002 mm |

| Lead Time | For standard operations, lead times can be as short as 2-3 days, while more complex projects might require up to 2 weeks. |

5 Axis CNC Machining Design Guidelines

| Recommended Size | |

|---|---|

| Minimum Feature Size | Minimum feature size should be no less than 0.5 mm in width or depth to ensure structural integrity. |

| Linear Dimension | Maintain a precision within ±0.005 mm for linear dimensions to ensure accuracy across the machined part. |

| Hole Diameters (not reamed) | Holes can be machined with diameters starting from 1 mm up to 40 mm without reaming for precision sizing. |

| Shaft Diameters | Shaft diameters should range from 2 mm to 300 mm, considering the tool accessibility and torque requirements. |

| Threads and Tapped Holes | Threads from M2 to M24 can be machined. Ensure to provide adequate relief at the bottom of tapped holes. |

| Text | Minimum text height of 1.5 mm with a depth of 0.5 mm for clarity after machining. |

Arapidtools 5-axis Machine Shop

Explore our impressive lineup of high-performing 5-axis machining centers, including top-tier horizontal and vertical machining centers. With a fleet of 9 advanced 5-axis CNC machines, we are well-equipped to handle large-scale production while ensuring precision and efficiency. Our skilled technicians, combined with these cutting-edge machines, enable us to meet diverse manufacturing needs across various industries. Trust our services to deliver results tailored to your specifications.

Contact us for a free quote or more information about Arapidtools’ 5-axis CNC machining services. We offer custom solutions for precise, durable, and robust parts in a variety of shapes and sizes to fulfill your project requirements.

Simultaneous 5 Axis vs 3+2 Axis CNC Machining

Simultaneous 5-Axis Machining

Fast, effective, and continuous 5-axis CNC machining with improved transitioning and surface quality. Here, we use 5-axis machining center that can continuously adjust the movements on all five axes without stopping. Our 5-axis CNC machining has intelligent functionalities to ensure efficient continuous processes and transitions.

3+2 Axis Machining

Leverage the advantages of optimal 3+2 axis machining technology for your unique applications. This process keeps the part fixed in a specific orientation, enabling standard 3-axis machining operations while maintaining flexibility. Our 3+2 axis machining utilizes shorter, more rigid cutting tools to provide your parts with enhanced dimensional stability. Achieve complex CNC machined parts with tight tolerances, all while reducing costs and cycle time.

Trunnion-Style vs Swivel-Rotate-Style 5-Axis Machining

Trunnion-style machining centers

The design features a fixed table and a spindle that moves and rotates along two axes. This configuration allows for machining complex parts from multiple angles in a single setup, improving efficiency and reducing the need for multiple repositioning. It is particularly advantageous for heavy or larger workpieces, as the stable support provided by the fixed table ensures precision and stability throughout the process.

Swivel-Rotate-Style machining

Also known as a table-table configuration, this setup involves affixing the part to a table that rotates and tilts, while the spindle stays in a fixed position. This style is especially beneficial for intricate parts that require high precision, offering excellent accessibility to various features of the part. It is well-suited for handling smaller, more delicate components, ensuring precision and flexibility throughout the machining process.

Why Choose Us

/01

High Quality Parts

/02

Fast Lead Time

/03

Engineering Support

No matter when or where, navigate your CNC milling projects with confidence. Our seasoned specialists provide expert guidance at every stage, ensuring design optimization and superior output quality.

Advantages of 5 Axis CNC Machining

- Complex Geometries: Allows for the machining of intricate designs and complex shapes from any angle, reducing the need for multiple setups.

- Enhanced Accuracy: Minimizes handling errors associated with multiple setups, improving the overall accuracy of the finished product.

- Improved Surface Finish: The tool can maintain an optimal angle relative to the surface, enhancing the quality of the surface finish and reducing the need for secondary finishing operations.

- Use of Shorter Cutting Tools: Enables closer positioning of the tool to the workpiece, which reduces tool deflection and vibration, leading to more precise cuts.

- Increased Productivity: Reduces overall production time by combining what traditionally requires several machine setups into a single setup.

- Material Conservation: Efficient tool paths and advanced control minimize material waste, which is especially beneficial when working with expensive materials.

Applications

Applications of 5 Axis CNC Machining

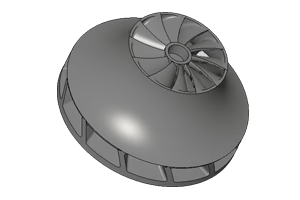

- Aerospace Components: Crafting airframe structures and engine parts that require complex contours and must withstand extreme conditions. Examples include turbine disks, compressor blades, and swivel bearings.

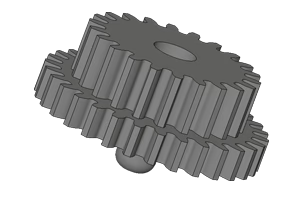

- Automotive Parts: Producing transmission gears, engine mounts, and complex hub assemblies. These parts often involve intricate features and deep pocket cuts, which 5-axis CNC machining handles efficiently.

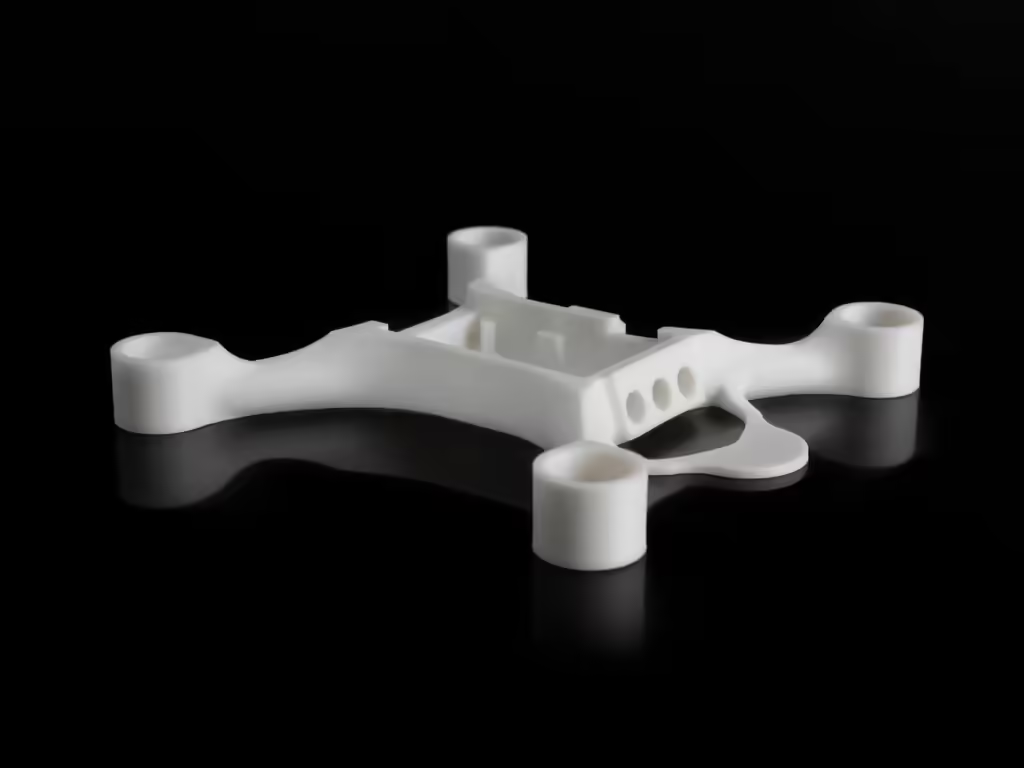

- Medical Implants: Manufacturing bespoke medical implants such as hip joints and cranial plates. These require highly customized shapes and smooth finishes to match patient anatomy.

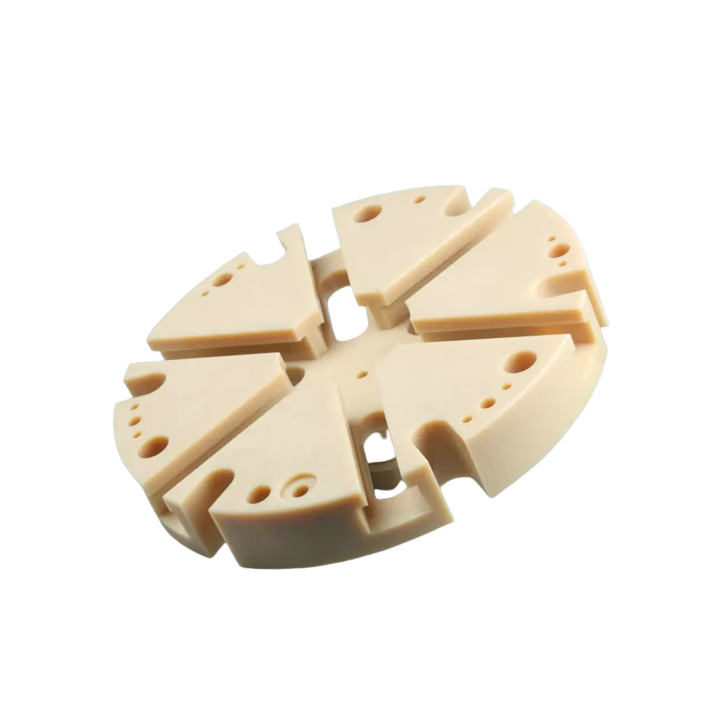

- Die and Mold Making: Creating complex molds, dies, and fixtures that are crucial for the mass production of other products. This includes injection molds and stamping dies with detailed features and tight tolerances.

- Marine Parts: Building parts for boats and other marine vehicles, such as propellers and hull components. These parts often have complex designs and require precise machining to ensure performance and durability in harsh environments.

- Energy Sector Components: Machining parts used in power generation equipment, such as wind turbine hubs and solar panel frames. These require high precision to ensure efficiency and long-term reliability.

5 Axis CNC Machining FAQs

What’s the difference between 5-axis machining and 3-aixs machining?

The main difference between 5-axis and 3-axis machining lies in their respective capabilities and the complexity of parts they can handle. 3-axis machining operates along three axes (X, Y, and Z), suitable for parts with relatively simple geometries. It typically requires multiple setups and repositioning to reach all sides of the part. Conversely, 5-axis machining adds two additional rotational axes, allowing the cutting tool to approach the part from virtually any direction. This capability makes it ideal for complex shapes, reducing setup times and improving precision by minimizing handling.

When should I choose 5-axis CNC machining?

Opt for 5-axis CNC machining when manufacturing parts with complex geometries, intricate details, or when high precision is critical. This technology is ideal for parts that require machining from multiple sides in a single setup or where multiple tool angles are necessary to achieve the design. Industries such as aerospace, medical, and automotive, where the geometrical complexities and tight tolerances are common, significantly benefit from 5-axis machining. It is also preferable when aiming to reduce lead times and improve surface finishes without compromising on detail.

How much does your 5-axis milling service cost?

Can 5-axis machining provide tight tolerance?

Yes, 5-axis CNC machining is renowned for its ability to achieve exceptionally tight tolerances. It can typically maintain precision within ±0.005 mm. This high level of accuracy is due to the machine’s capability to access five sides of a part in a single setup, reducing the number of setups required and minimizing errors associated with repositioning. The simultaneous movement along five axes allows for closer tool paths, ensuring precise adherence to design specifications, especially for complex geometries.

What is the tolerance of 5 axis CNC machining?

Let's Start A New Project Today