Selective Laser Sintering (SLS) 3D Printing Service

Start A New SLS Quote

STEP | STP | SLDPRT | IPT | PRT | SAT files

- All uploads are secure and confidential.

What Is Selective Laser Sintering?

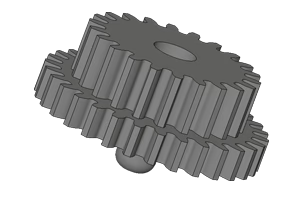

Selective Laser Sintering (SLS) is a powder-based 3D printing method where a laser selectively fuses material layers to form a complete part. The laser outlines the cross-sectional pattern of a 3D design onto a powder bed. Once a layer is completed, the platform descends, and another layer is added on top, repeating until the entire object is constructed.

SLS stands out for its applicability in functional scenarios, especially for parts with features like snap fits, living hinges, and various mechanical joints. The broad spectrum of materials and the size of platforms available make SLS an excellent choice for directly producing items that need to be strong and heat-resistant.

Our SLS 3D Printing Service

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

The table below depicts the general tolerances for industrial-grade SLS services. Stresses during the build, support strategy and other geometry considerations may cause deviation in tolerances and flatness. Improved tolerances may be possible with a manual quote review, after successful completion of a prototype build, and must be approved on a case-by-case basis.

SLS 3D printing materials

- Flexible TPU

- PA 12 Nylon - Black

- PA 12 Nylon - White

- PEBA 2301 - Black

- PEBA 2301 - White

- Polypropylene

SLS 3D printing finishing options

As-printed

The part is de-powdered and cleaned via air blasting, leaving a natural grainy texture. Depending on the material used, the finished product is typically white or black.

Short peening

The part is blasted with small spherical media, such as glass or plastic beads, at controlled velocities. The impact creates beneficial compressive stresses in the part and smooths the surface, enhancing mechanical properties and improving the finish.

Vibro polishing

Finished parts are placed in a vibrating container filled with polishing media, such as ceramic or plastic beads. The continuous vibration causes the media to gently abrade the parts’ surfaces, gradually reducing surface roughness and improving finish quality.

Dyeing

Parts are dyed by immersion in a warm color bath. The dye penetrates the part’s surface to a depth of 0.25 mm to 0.5 mm. Available colours include black, blue, red, green, and yellow.

Custom

You can specify custom finishes such as painting and electroplating. Note that custom finishes require manual review and quoting and may be subject to approval.

Multi-industry applications of 3D Printing services

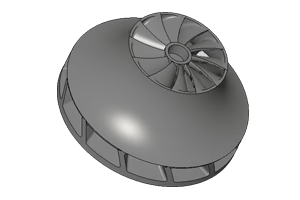

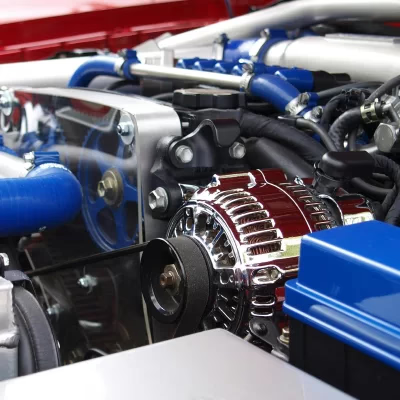

Automotive

Our low-volume manufacturing services is the ideal manufacturing solution for on demand automotive parts.

Aerospace

The durability and precision that our precison manufacturing services provide meets the sophisticated needs the different phases of the aerospace industry required.

Consumer Goods

Strong partnerships with leading consumer manufacturers help us accelerate the prototyping process and improve the consumer goods industry.

Medical Devices

Medical supplies manufacturers, tech startups, and research labs benefit significantly from the prototyping solutions we provide.

Robotics

Our industrial-grade robotics prototyping and parts manufacturing services aid in the continuous evolution of the robotics market.

Let's Start A New Project Today