Selective laser melting (SLM)

Start A New SLM Quote

STEP | STP | SLDPRT | IPT | PRT | SAT files

- All uploads are secure and confidential.

How Does Metal 3D Printing Work?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Our SLM 3D printing service

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

SLM 3D printing materials

- Aluminium Al-Si10Mg

- Cobalt Chrome, CoCr

- Copper

- Inconel 718

- Inconel 615

- Stainless Steel 316L / 1.44.4 / X2CrNiMo17-12-2

- Stainless Steel 17-4PH / 1.4542 / X5CrNiCuNb16-4

- Titanium Grade 5 / 3.7164 / 3.7165 / Ti-6Al-4V

SLM 3D printing finishing options

As-printed

Part is de-powdered and cleaned, leaving a natural metallic colour, depending on the metal. Smooth surface finish with a slightly grainy texture. No visible layer lines.

Bead blasting

Parts are blasted with fine, abrasive beads, typically made of glass or ceramic,, under high pressure. This process removes surface imperfections, smooths out rough areas, and creates a uniform matte or satin finish.

Custom

You can specify custom finishes such as coating, electroplating, anodising, coating, brightening, etc. Note that custom finishes require manual review and quoting and may be subject to approval.

Advantages of SELECTIVE LASER MELTING (SLM) 3D printing

- Large range of metals available

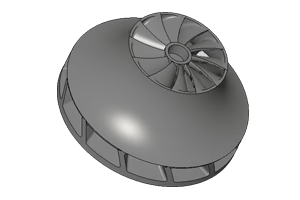

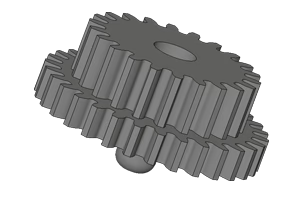

- Ability to realize complex shapes or internal features (which would be incredibly difficult or expensive to achieve via traditional manufacturing)

- Reduced lead times, due to no need for tooling

- Part consolidation, allowing the production of multiple parts at the same time

Drawbacks of SELECTIVE LASER MELTING (SLM) 3D printing

- Expensive, especially if parts aren’t optimized or designed for the process

- Specialized design and manufacturing skills and knowledge needed

- Limited currently to relatively small parts

- Rough surface finish

- Lots of post-processing required

Multi-industry applications of 3D Printing services

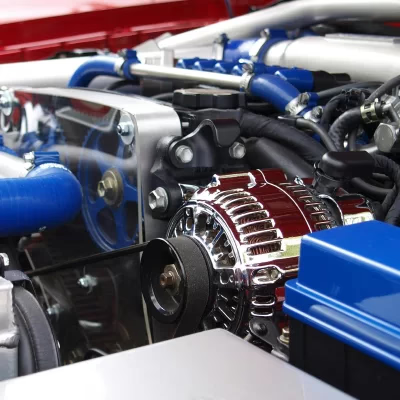

Automotive

Our low-volume manufacturing services is the ideal manufacturing solution for on demand automotive parts.

Aerospace

The durability and precision that our precison manufacturing services provide meets the sophisticated needs the different phases of the aerospace industry required.

Consumer Goods

Strong partnerships with leading consumer manufacturers help us accelerate the prototyping process and improve the consumer goods industry.

Medical Devices

Medical supplies manufacturers, tech startups, and research labs benefit significantly from the prototyping solutions we provide.

Robotics

Our industrial-grade robotics prototyping and parts manufacturing services aid in the continuous evolution of the robotics market.

Let's Start A New Project Today