Stereolithography SLA 3D printing service

Fast•Cost-effective Make your show-and-tell prototype with extremely high-resolution in as fast as 3 day!

Start A New SLA Quote

STEP | STP | SLDPRT | IPT | PRT | SAT files

- All uploads are secure and confidential.

What is Stereolithgraphy?

Our SLA 3D printing service

| Requirement | Specification |

| Min. Wall Thickness | 0.6mm for unsupported walls, 0.4mm for supported walls on both sides |

| Layer Height | 25 µm to 100µm |

| Max. Build Size | 1400x700x500mm |

| Dimension Tolerance | ±0.2mm (For >100mm, apply 0.15%) |

The table below depicts the general tolerances for industrial-grade stereolithography (SLA) services. Stresses during the build, support strategy and other geometry considerations may cause deviation in tolerances and flatness. Improved tolerances may be possible with a manual quote review, after successful completion of a prototype build, and must be approved on a case-by-case basis.

SLA 3D printing materials

- Standard Resin - Black

- Standard Resin - White

- Standard Resin - Grey

- Standard Resin - Clear

- Formlabs Tough Resin 2000 - ABS-like

- Formlabs High Temp Resin

- Formlabs Durable Resin - PP-like

- Formlabs Rigid Resin 4000

- Formlabs Grey Pro Resin

- Formlabs Flexible Resin 80A - Silicone-like

SLA 3D printing finishing options

As-printed

Support structures, if present, will be removed, and support surface nibs will be lightly sanded until smooth, ensuring a high-quality finish.

Vapour polished

Vapour polishing is done to increase the smoothness of the surface.

Custom

You can specify custom finishes such as painting and electroplating. Note that custom finishes require manual review and quoting and may be subject to approval.

SLA 3D Printing Advantages

- Surface & Detail: SLA has tolerances of +/-.004” per inch, and resin surface is ideal for post-processing like polishing and painting.

- Cost Saving: SLA is one of the cheapest method for rapid prototyping while preserving a good surface quality and accuracy.

- Geometry: SLA allows to integrate multiple components as well as thin-walled objects and intricate geometries that traditional method won’t be capable of.

- Turnaround: SLA 3D printed parts do not require tooling which reduces the manufacturing lead time from weeks to days, allowing for faster innovation and speed to market.

- Material Selection: There’re various material with special properties like toughness, heat resistance, flexibility, which simulates the end products.

- Scalable Volume: Multiple, identical parts can be built on a single platform at one time, greatly increasing production efficiency.

SLA 3D Printing Drawbacks

- Durability: Photopolymers are not stable over time and most resins don’t have balanced impact/heat resistance.

- Scale Effect: The unit cost and lead time will not be reduced as much as casted or molded parts.

Multi-industry applications of 3D Printing services

Empowering a wide range of industries with exceptional products: automotive, industrial machinery, medical, aerospace, consumer electronics, and robotics.

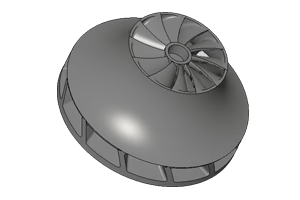

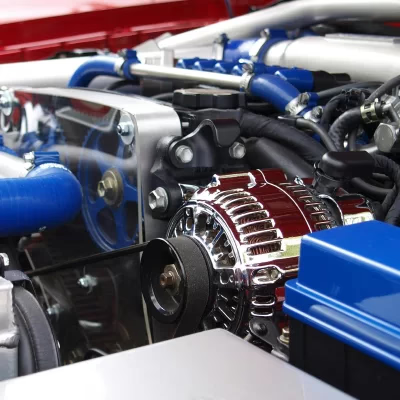

Automotive

Our low-volume manufacturing services is the ideal manufacturing solution for on demand automotive parts.

Aerospace

The durability and precision that our precison manufacturing services provide meets the sophisticated needs the different phases of the aerospace industry required.

Consumer Goods

Strong partnerships with leading consumer manufacturers help us accelerate the prototyping process and improve the consumer goods industry.

Medical Devices

Medical supplies manufacturers, tech startups, and research labs benefit significantly from the prototyping solutions we provide.

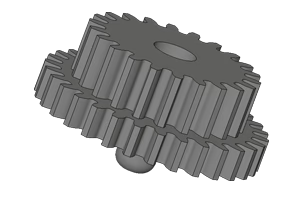

Robotics

Our industrial-grade robotics prototyping and parts manufacturing services aid in the continuous evolution of the robotics market.

Let's Start A New Project Today