Rapid Prototyping with Arapidtools

Rapid CNC machining, injection molding, sheet metal fabrication, 3D printing services. Lead time as fast as 1 day.

Start A Rapid Prototyping Quote

STEP | STP | SLDPRT | IPT | PRT | SAT files

- All uploads are secure and confidential.

What is Rapid Prototyping

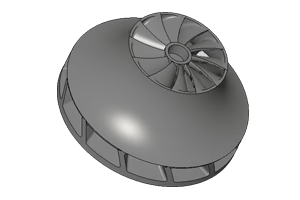

Rapid prototyping quickly converts early-stage design concepts into physical models, offering a fast and cost-effective way to see ideas in reality. This approach is particularly effective through technologies such as 3D printing, CNC machining, and more, with the ability to deliver prototypes typically within 1-3 business days.

Opting for prototyping is essential for speeding up the design process while reducing the financial and operational risks associated with new product development. It enables thorough testing and refinement of designs, ensuring that each iteration is an improvement on the previous one. This process is critical for making informed decisions early in the development cycle, minimizing the risk of expensive alterations later on.

Rapid prototyping quickly converts early-stage design concepts into physical models, offering a fast and cost-effective way to see ideas in reality. This approach is particularly effective through technologies such as 3D printing, CNC machining, and more, with the ability to deliver prototypes typically within 1-3 business days

Our Rapid Prototyping Services

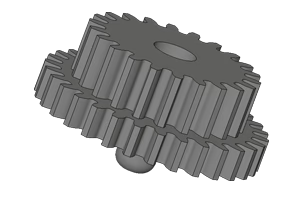

Rapid CNC Prototyping Service

CNC machining, encompassing both CNC milling and CNC turning, is an ideal choice for rapid prototyping when parts need to be evaluated in their final material form. This method allows prototypes to be crafted from fully dense stock, resulting in accurate and durable models. Arapidtools specializes in machining a wide range of metals and plastics, offering versatility to meet your project’s specific requirements. Our rapid CNC prototyping services deliver high-quality machined prototypes quickly, often within just one day. This speed, combined with our cost-effective pricing, enables engineers to order multiple prototypes at once, ensuring swift and thorough product evaluations.

Choosing Arapidtools for your CNC prototyping needs means benefiting from our expertise and dedication to precision. We offer various expedite options to ensure that urgent projects are completed on time. Our market-based pricing model ensures affordability without sacrificing quality. With Arapidtools, you receive detailed and accurate prototypes that accelerate product development from initial design to final production.

Maximum Part Size:

CNC Milling: 4000×1500×600 mm

CNC Turning: 200×500 mm

Standard Lead time: 1 day

Tolerance: 0.001 inches

Rapid Prototype Injection Molding Services

Injection molding is an excellent choice for prototyping when you need highly durable and consistent parts for extensive testing. This method is ideal for high-fidelity product evaluations and creating temporary bridge tooling during product launches. While traditional rapid injection molding typically requires a lead time of 2-3 weeks for initial parts, Arapidtools’s expedited services can deliver parts in as little as five days.

Choosing injection molding over 3D printing or CNC machining is advantageous when your project demands strict material properties or specific mechanical requirements that other methods may not achieve. Arapidtools excels in this area, offering high repeatability and near-final shapes with each prototype. Our expertise ensures that you receive reliable and precise prototypes, facilitating effective product development and testing.

Maximum Part Size: 1200×1000×500 mm

Standard Lead time: 2-3 weeks

Mold Cavity Tolerance: +/- 0.05 mm

Rapid 3D Prototyping Service

Max. Build Size: 1400x700x500mm

Standard Lead time: 4-6 days

Dimension Tolerance: ±0.2mm (For >100mm, apply 0.15%)

How to Choose The Right Rapid Prototyping Technique

| Advantages | Disadvantages | |

| Rapid CNC Machining | High precision and suitability for a variety of materials. Ideal for functional and durable parts. | Higher cost and longer lead times compared to some additive manufacturing processes. |

| Rapid Injection Molding | Excellent for high-volume production. Provides end-use, functional parts with fine details. | Upfront costs for molds are high, less economical for small quantities. |

| Rapid 3D Printing | Fast and cost-effective. Capable of complex geometries that are not possible with other methods. | Material properties might not match those of traditionally manufactured parts. Resolution varies by technology. |

Why Choose Us

/01

High Quality Parts

/02

Fast Lead Time

/03

Engineering Support

We Support From Prototyping to Production

01

Rapid Prototypes

Rapid prototypes are produced swiftly to facilitate immediate testing, feedback, and iteration, accelerating the development process.

02

Design & Engineering Validation

Prototyping services validate design and engineering specifications to ensure functionality and performance before mass production.

03

High Volume Production

The transition from prototype approval to high-volume production is streamlined to ensure quality and meet production deadlines efficiently.

Let's Start A New Project Today