Rapid Prototyping and On-Demand Production for

Aerospace Industry

Receive high-quality manufacturing services for your custom aerospace prototypes and production parts.

On-Demand Manufacturing for the Aerospace Industry

Powerful Capabilities

Instant Quotation

High Precision Parts

Fast Cycle Time

We Help From Prototyping to Production

01

Prototyping

Get high-quality prototypes for early-stage product development. Test your designs, make crucial material and design iterations, and prepare prototypes for testing. We’ll help you create prototypes based on your product’s requirements and design files. Depending on your needs, we’ll use cost-effective materials and processes to develop parts similar to the final product.

- Rapid material and design iterations

- Detailed prototypes for complex geometries

- Models similar to final products

02

Engineering Validation and Testing

Iterate quickly on precise functional prototypes to ensure all performance requirements are met. Our prototypes help you identify and mitigate design risks. Multiple iterations may be necessary to ensure the prototypes meet all functional requirements and performance metrics.

- Precision parts manufacturing

- Reliable design and engineering support

- Optimized material properties for custom designs

03

Design Validation and Testing

Effectively validate part functionality, performance, and appearance with a variety of material and surface finishing options. This stage helps you analyze the final feel and look of the aerospace component. Arapidtools offers a wide range of mechanical designs, materials, and finishes to meet your unique demands.

- High-quality parts for consumer and market testing

- Performance and appearance validation

- Durable and quality surface finishes

04

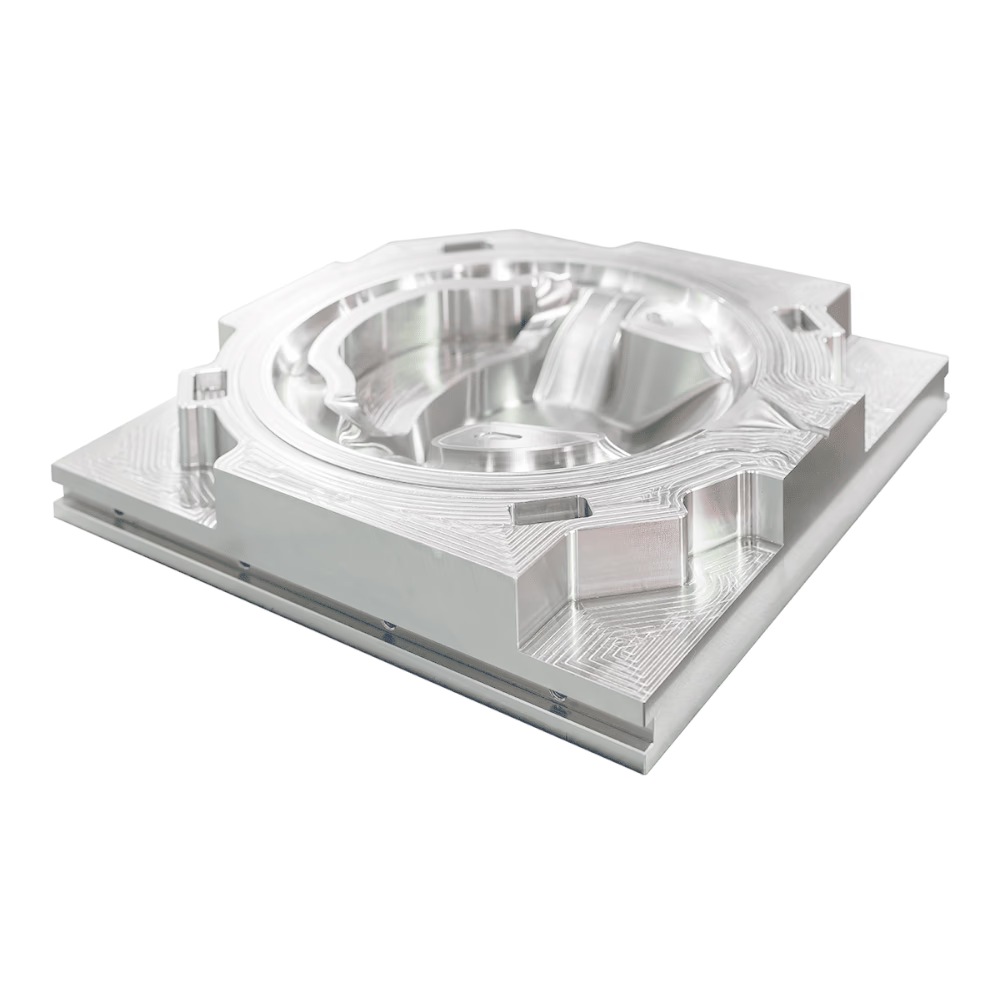

Production Validation and Testing

Prepare your design for full-scale production with production-grade manufacturing and advanced quality control. Gain control and receive feedback from the DVT stage to achieve production goals. Make final adjustments to your model for more effective manufacturing.

- Rapid delivery of production-quality parts

- Verification of manufacturing processes

- Low-volume production tooling

- Verify functionality of production-ready parts

05

Mass Production

Seamlessly transition from product testing to mass production of end-use parts. Access precise quality requirements and rapid delivery of final products. We manage your parts’ production with engineering expertise and advanced manufacturing processes. Our skilled technicians ensure high production yield and quality while reducing costs and lead times.

- High-quality custom end-use parts

- Tight tolerances on precision machined parts

- Secondary operations for better surface requirements

- Rigorous inspection and quality control

Our Manufacturing Services

Arapidtools offers top-notch manufacturing capabilities, ideal for rapid prototypes and custom production orders. Our self-owned factory and extensive Chinese manufacturing network are equipped to deliver complex, high-quality parts efficiently.

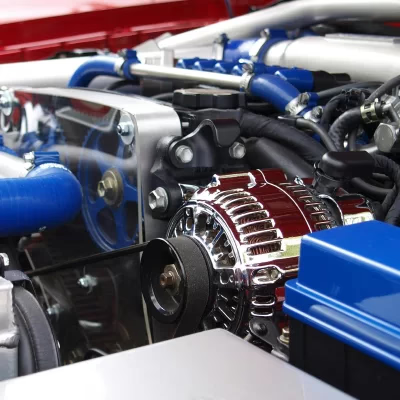

Automotive

Materials & Surface Finishes

Materials

Surface Finishes

Why Choose Us

Unleashing Our Company's Strengths

- Production capacity

- Strict quality control

Provide professional quality inspection report

- Standard Inspection with Formal Report

- CMM Inspection with Formal Report

- Source Material Certification

- Instant quote online

The online order page provides different parameters and processes to get a quote quickly

Applications of Aerospace Parts

Our advanced manufacturing capabilities enable us to rapidly produce a diverse array of aerospace components for specialized applications. Below are some of the common aerospace applications:

- Rapid tooling, brackets, chassis, and jigs

- Heat exchangers

- Custom fixturing

- Conformal cooling channels

- Turbo pumps and manifolds

- Fit check gauges

- Fuel nozzles

- Gas and liquid flow components

Our Services Cover Multiple Other Industries

Let's Start A New Project Today