Custom Online Compression Molding Services

Benefit from lower tooling costs than injection molding, while still producing high-quality, durable silicone parts.

- Parts shipped in as little as 14 days

Start A New Compression Molding Quote

STEP | STP | SLDPRT | IPT | PRT | SAT files

- All uploads are secure and confidential.

What is Compression Molding?

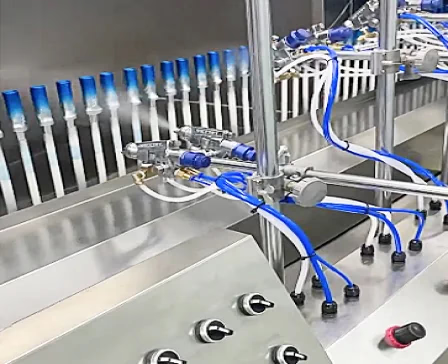

Compression molding is a manufacturing process where parts are shaped under pressure. Heated rubber is placed into one side of a mold, and then the other side is clamped down, compressing the rubber into the desired shape. The mold must be heated since the combination of pressure and heat allows the rubber to form correctly. The design of the mold for compression molding includes overflow grooves to manage excess material. It’s hard to predict exactly how much rubber is needed without some overflow. By using a bit more material, you ensure the mold fills completely, resulting in the intended product shape. The excess material, known as flash, needs to be trimmed away after the molding process is complete.

Custom Compression Molding Materials

Silicone

This is another material with top-notch heat resistance. Silicone is also flexible and ideal for electrical insulation. Like epoxy, silicone also flows well into the cavity and has no problem properly molding into intricate shapes. This makes it a great material for precision seals, gaskets, medical devices, and automotive components.

Precision Molded Tolerance

| With Drawing | Without Drawing | |

| Linear Dimension | +/- 0.01 mm +/- 0.004 inch | SPI Commercial |

| Hole Diameters | +/- 0.005 mm +/- 0.002 inch | SPI Commercial |

Compression Molding Finishing Options

All finishes meet SPI standards

Finishes

SPI polished finishes and MT (MoldTech) textured finishes.

Pad Printing

Transforming a flat, ink-based 2D design onto a three-dimensional surface.

Color Matching

Standard colors plus matching to Pantone or RAL number.

Let's Start A New Project Today