Quality Assurance at Arapidtools Network

Leveraging advanced manufacturing processes, rigorous quality assurance measures, and strict adherence to industry standards, we deliver high-quality, precision-engineered parts designed for durability. Whether you need prototypes or on-demand production, our commitment ensures your parts meet the highest standards of performance and reliability.

Our Policy On Quality

Scientific Management

Establish standardized and scientific management concepts; Formulate reasonable working methods and operating codes; Train excellent employees with first-class skills; Improve production efficiency.

Lean Production

Quality and Efficiency

Through the implementation of the overall quality management system, during each process in the production strengthening quality control and inspection, ensuring the optimization of the company’s processes, and the effective communication between customers and departments, also training the quality awareness of employees, pushing to upgrade continually implement technology, and efficiently manufacturing high-quality products.

Innovation and Enterprise

Establish a learning organization system, implement knowledge management, collect and organize the knowledge for corrective and preventive measures, production technology from professional technicians or departments, business data or production experiences to form important valuable resources of company, provide continuous training opportunities for employees, summarize experience, encourage innovation and enhance company cohesion.

Let Arapidtools be the safest and most dependable choice for your next manufacturing project.

Inspection and Quality Control Procedures in Our CNC Machine Shop

Our quality assurance process spans the entire project lifecycle, from initial RFQs to final production shipment.

It begins with two independent purchase order reviews to ensure clarity and alignment on dimensions, materials, quantities, and delivery timelines, eliminating any potential discrepancies. Next, experienced team members overseeing setup and production conduct detailed assessments, generating individual inspection reports for each required operation. Special quality requirements and instructions are meticulously documented, with inspection intervals tailored to the part’s tolerances, quantities, or complexity.

By closely monitoring and analyzing every stage of manufacturing, we reduce risk, minimize part-to-part variation, and guarantee consistent, dependable quality for every component, every time.

Quality-Driven Rapid Manufacturing

We ensure consistent quality across every part, product, and project through meticulous attention to detail, innovative problem-solving, and ongoing research into advanced materials and processes. By investing in cutting-edge technology and fostering a skilled team, we deliver professional rapid manufacturing you can rely on.

- Design for Manufacturing (DFM) analysis for all projects

- Production capacity and planning oversight (PMC)

- Rigorous inspection of incoming raw materials

- In-process sampling and quality checks (IPQC)

- Effective management of nonconforming products with corrective and preventive measures

- Comprehensive final inspections, testing reports, and certifications (OQC)

- Biannual customer satisfaction surveys to exceed your expectations

Quality Of Documentation

We provide comprehensive quality documentation for all projects, including inspection reports, material certifications, and compliance documentation.

Visual Inspection and Testing

We ensure that each product meets the customer’s requirements for color, texture and overall appearance.

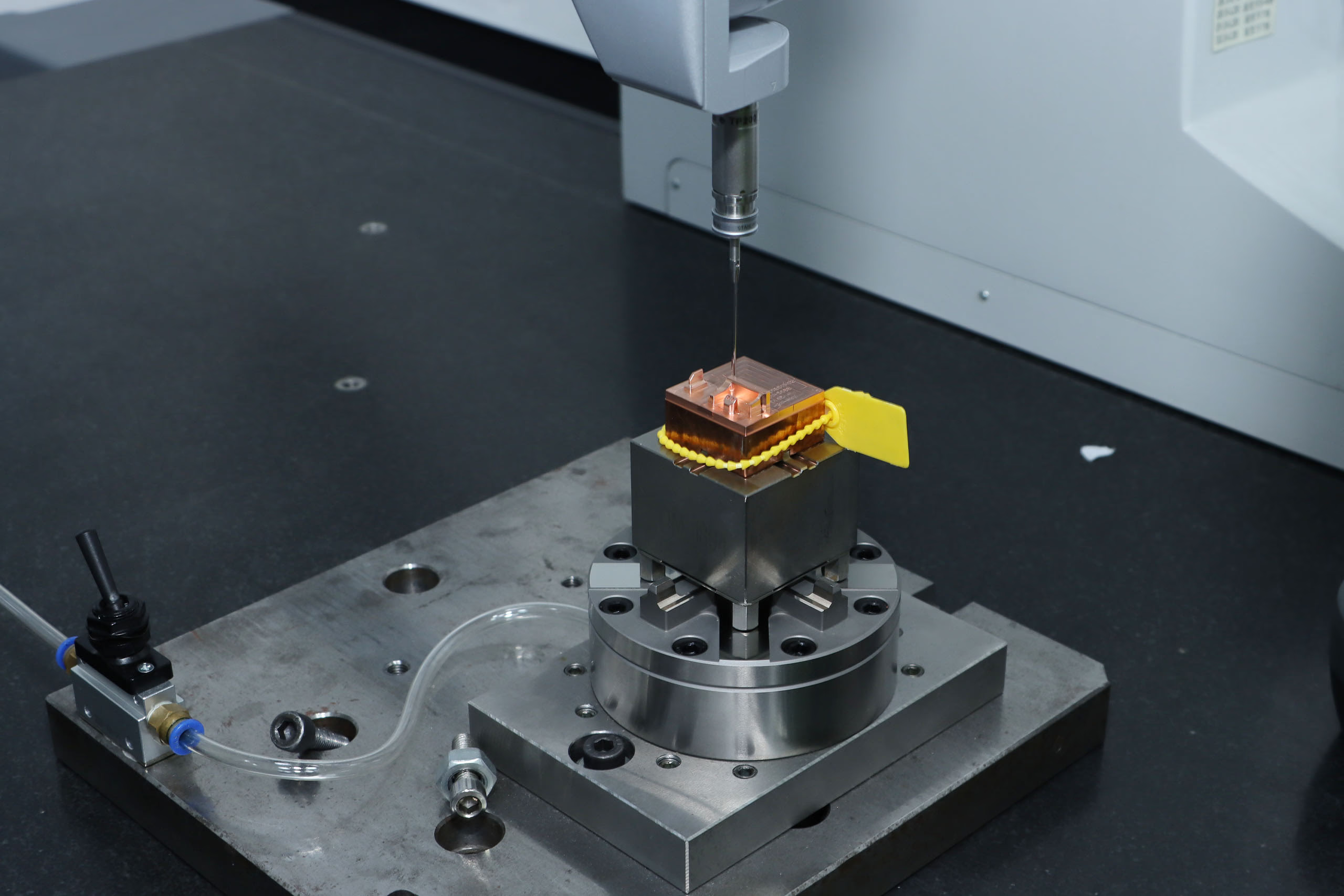

Dimensional Inspection

We use vernier calipers, micro calipers and height gauges for simple structures and CMM machines for complex products to ensure accurate measurements.

Performance Check

We evaluate component functionality to ensure that parts such as threaded holes fit properly during assembly.

First Article Inspection

We provide a final inspection report detailing all inspection procedures and results.

RoHS Reporting

We can provide a RoHS report upon request. This report confirms that a material complies with RoHS standards.

Manufacturing Standards

CNC Machining Manufacturing Standards

Injection Molding Standards

3D Printing Manufacturing Standards

Let's Start A New Project Today